The Hidden Costs of Poor Measurement Accuracy

The Hidden Costs of Poor Measurement Accuracy

Blog Article

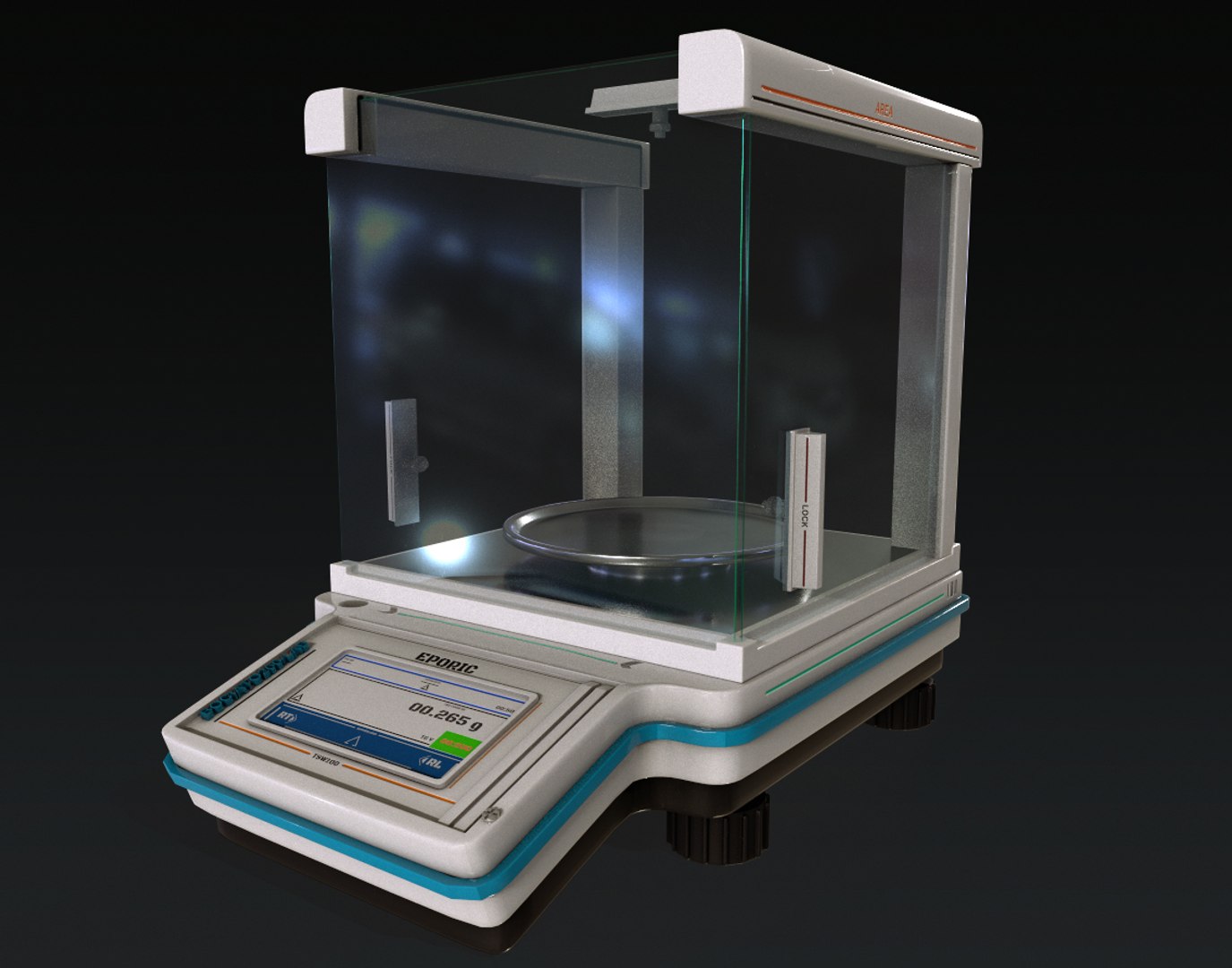

In the world of scientific research and industrial applications, the accuracy of measurements can often mean the difference between success and failure. High-precision laboratory analytical balances play a crucial role in ensuring that results are reliable and reproducible. However, many laboratories overlook the hidden costs associated with poor measurement accuracy. These costs can extend far beyond mere financial implications, affecting research outcomes, compliance with industry standards, and overall operational efficiency.

W&J Instrument, a professional manufacturer and supplier of various electronic balances, moisture analyzers, viscometers, and other laboratory instruments, understands the significance of precision in measurement. Relying on equipment that lacks the necessary accuracy can lead to erroneous data, wasted resources, and diminished credibility. By examining these hidden costs, laboratories can better appreciate the importance of investing in high-quality analytical balances and the impact that precision has on their overall success.

Understanding Measurement Accuracy

Measurement accuracy is crucial in a laboratory setting as it directly impacts the reliability of results. High-precision laboratory analytical balances are designed to provide exact measurements that scientists rely on for experiments and analyses. When balances produce inaccurate readings, it can lead to erroneous conclusions and potentially costly decisions based on faulty data.

Factors influencing measurement accuracy include environmental conditions, equipment calibration, and the inherent quality of the instruments used. For instance, high-precision balances must be kept on stable surfaces away from vibrations and air currents to minimize errors. Regular calibration with certified weights is essential to ensure that the balance is measuring correctly and consistently over time.

In the context of W&J Instrument's offerings, the significance of measurement accuracy cannot be overstated. As a manufacturer of electronic balances and laboratory instruments, W&J prioritizes the development of devices that maintain high levels of precision. Investing in high-quality instruments helps laboratories avoid the hidden costs associated with poor measurement accuracy, ensuring that research and production processes run smoothly and effectively.

Impact on Product Quality

Calibration Weights for Laboratories

In high-precision laboratory environments, the accuracy of measurements can have profound implications on product quality. When instruments such as analytical balances are miscalibrated or function with poor measurement accuracy, the resulting data can lead to incorrect formulations or assessments. For industries like pharmaceuticals or food production, even the slightest error in weight can compromise the entire batch, resulting in products that fail to meet rigorous quality standards.

Moreover, the relationship between measurement accuracy and reproducibility cannot be overstated. Inconsistent measurements due to faulty analytical balances can introduce variability that impacts not only the quality of individual products but also the overall reliability of production processes. This can lead to increased waste, rework, and ultimately higher operational costs as manufacturers strive to achieve consistency and compliance with industry regulations.

Additionally, the repercussions of poor measurement accuracy extend beyond product quality to customer trust. When products fail to meet specified standards, it can damage a brand's reputation and lead to loss of consumer confidence. Companies like W&J Instrument, which specializes in high-precision laboratory instruments, highlight the necessity of accurate measurement tools to ensure that manufacturers can consistently deliver high-quality products and foster long-term relationships with their clients.

Financial Implications

The financial repercussions of poor measurement accuracy in laboratory settings can be profound and far-reaching. When high-precision analytical balances are not utilized, the risk of inaccurate results increases, leading to potential wastage of materials and time. This inefficient use of resources translates directly into higher operational costs, as labs may have to repeat experiments or tests to obtain reliable data. Consequently, any financial savings anticipated from using lower-quality equipment are often negated by the additional expenses incurred from such errors.

Moreover, inaccurate measurements can compromise the integrity of research and product development processes. In industries where compliance with regulatory standards is crucial, like pharmaceuticals and food production, poor measurement can lead to non-compliance penalties, product recalls, or even legal liabilities. Companies relying on subpar measuring instruments may find themselves facing significant fines or damage to their reputation, resulting in a loss of customer trust and future sales opportunities. Investing in high-precision laboratory analytical balances ultimately serves as a safeguard against these liabilities.

The initial investment in high-precision equipment, such as those from W&J Instrument, can yield significant long-term financial benefits. By ensuring accurate measurements, laboratories can enhance productivity, reduce material waste, and improve the overall quality of their outputs. This not only strengthens a company’s market position but also translates into increased profitability over time. Thus, the cost of upgrading to reliable instruments is not merely an expense but a strategic investment that can enhance financial performance and sustainability in the competitive landscape of laboratory operations.

Choosing the Right Instruments

Selecting the right high-precision laboratory analytical balances is crucial for achieving accurate measurements and ensuring the integrity of experimental results. When assessing your options, it is essential to consider the specific requirements of your application, such as the weight range, readability, and sensitivity of the balance. Each laboratory has unique needs, whether it is for precise formulation, quality control, or research purposes. Therefore, investing time in understanding these needs will guide you in making the optimal choice.

Another important factor to evaluate is the reliability of the manufacturer. W&J Instrument stands out as a trusted provider of various electronic balances and laboratory instruments. Their commitment to quality and precision ensures that you are getting reliable equipment that performs consistently over time. Look for features such as calibration procedures, certification standards, and customer support when sourcing your instruments, as these can significantly influence the accuracy of your measurements.

Lastly, consider the integration of your analytical balances with existing laboratory systems and workflows. Ensuring compatibility with data management systems can enhance efficiency and reduce human error. High-precision laboratory balances should seamlessly connect with software for data recording and analysis. This integration not only streamlines operations but also supports better decision-making based on reliable data, ultimately reducing the hidden costs of measurement inaccuracies.

Report this page